A history of the EPROM in the Soviet Union

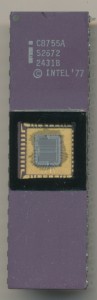

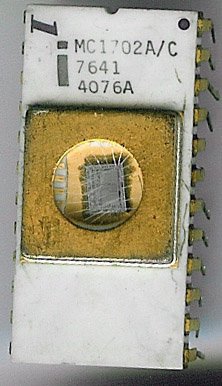

In 1971 Intel came out with the first memory that could be not only programmed by the user, but could be erased with UV light and programmed again. This was the 1701 EPROM (quickly revised into the 1702 EPROM and 1702A). It was 2048 bits (256×8), used PMOS, and required three voltage (+5V, +12V and -12V) to operate, and each data line required a strobed -48V pulse for programming.

The 1701 was introduced to the world in the May 10, 1971 issue of Electronics Magazine in an article written by Dov Frohman, the inventor of the EPROM. Today Intel is more known for, and remembered by their microprocessors, but until the early 1980’s it was EPROM’s that carried the company. They accounted for the largest share of profits at Intel for over a decade.

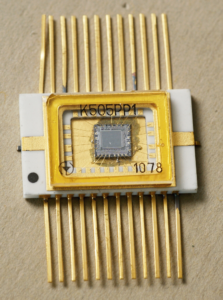

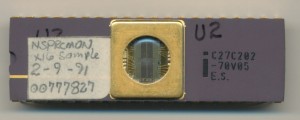

K505RR1

The first EPROM chip produced in the Soviet Union was the K505RR1, developed by the Kyiv Research Institute of Microdevices and manufactured by the Kvazar factory in Kyiv, Ukraine. The chip is a 2048-bit (256×8) electrically programmable read-only memory with ultraviolet erasure. It is an analogue of the 1702А.

They supported up to 20 (they wore out quite quickly) overwrite cycles and had a data retention period in on state of not less 5000 hours. This is one of the only EPROM chips manufactured in the flat pack package. NEC made a 2Mbit flat pack EPROM in the 1990s, quite a strange beast.

|

|

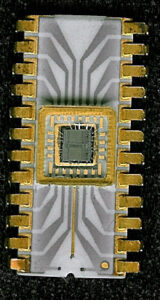

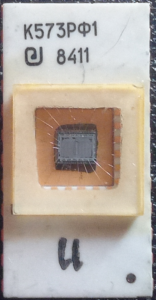

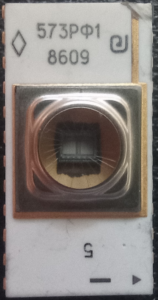

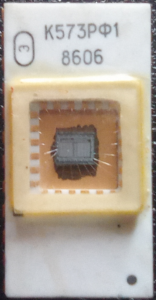

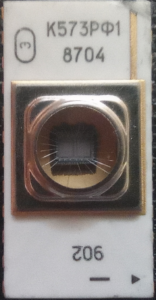

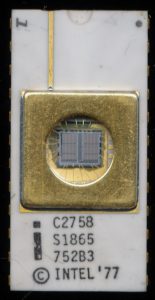

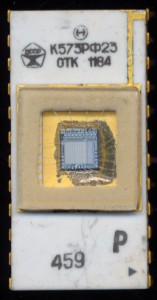

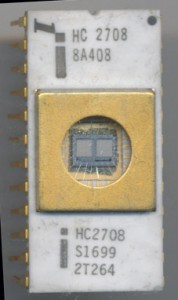

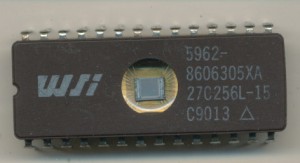

K573RF1

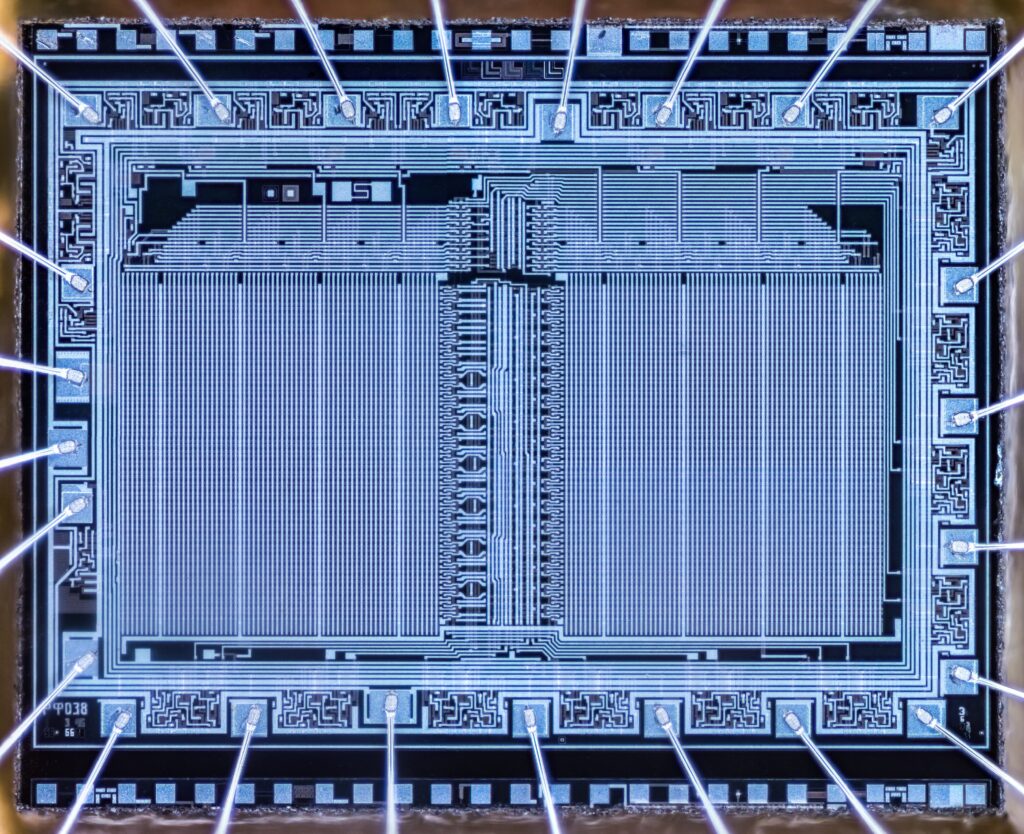

Analogue of the i2708. The microcircuit is a read-only memory device with a capacity of 8 Kbit (1024х8). Supply voltages of 12v, 5v, -5v. Data Retention period in on state is not less 15000 hours. Number of write cycles at least 100. (a nice improvement over the previous generation)

Microcircuits were manufactured at two factories: Novosibirsk Factory Vostok and Novosibirsk Electrovakuum Factory (NEVZ). The ‘3’ logo is an export version.

|

|

|

|

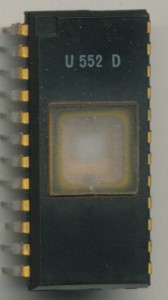

|

On microcircuits with a metal cover, you can see that a part of the conductor connecting this cover and GND pin has been mechanically removed. In electrochemical coating, it’s necessary that all surfaces on which gold is deposited in this case be connected to each other. But the K573RF1 chip has three power supplies. And minus 5 volts is applied to the die substrate. Part of the conductor has been removed to avoid a possible short circuit.

In the manufacture of dies, it happens that several memory cells turn out to be damaged. The manufacturer blocks access to damaged part of the die by connecting one or two input addresses to ground or a power supply. Either guarantees the operation of only half of the data bus of the microcircuit. K573RF11, K573RF12 have an information capacity of 4 Kbit (512×8) , K573RF13, K573RF14- 4 Kbit (1024×4).

Posted in:

EPROM of the Day