Processor News Round-up: More cores in more places

The last week has been filled with new processor announcements, mainly for phones, but cameras as well. (yes they run some powerful processors now too).

TI is barely shipping products with its dual-core OMAP 4 applications processor and has already announced its successor, the OMAP 5. The OMAP 5 will be a 2GHz dual core ARM Cortex-A15 (the next ARM generation after the A9). It also includes a pair of ARM Cortex-M4 processor. the Cortex-M4 is a 150-300MHz microcontroller oriented processor. This will allow the OMAP 5 to run basic background tasks on the slower (lower power) cores while reserving the high power cores for tasks that actually need them, increasing battery life.

Broadcom continues its drive to enter the smart phone business with the BCM28150, a 1.1GHz dual core ARM Cortex-A9 compatible with Google Android. In December they released the BCM2157, a 500MHz dual core ARM11 processor for low-end smart phones

Samsung decided to rename the Orion processor (announced back in November) to the Exynos 4210. A bit of a mouthful compared to Orion.

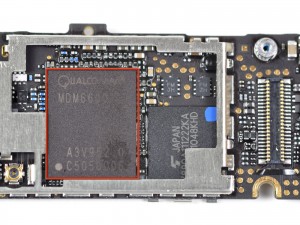

Qualcomm showed off the APQ8060 in HP’s new TouchPad. This is a dual core version Snapdragon processor we have become very familiar with. Qualcomm has an architecture license from ARM so they are free to design their own cores without having to stick to ARMs own implementations (such as Cortex-A9 etc). This gives Qualcomm more flexibility to design in features they need, and tweak design more best efficiency.

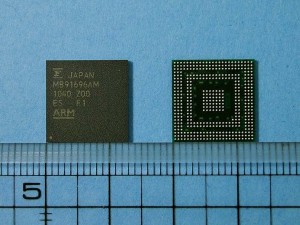

Smart phones aren’t the only ones getting new processors. Digital cameras now require immense amount of processing power (especially to handle 1080p video recording. Fujitsu (yah, they still make a lot of processors) announced the Milbeaut MB91696AM. This is a dual core ARM processor with many other DSP functions capable of handling 14Mpixel shooting at 8fps, as well as full HD video.