The General Automation GA-16 16-bit CPU

General Automation was founded in 1968, just prior to the beginning of the microprocessor boom of the 1970’s. They were founded by Burt Yale, a former aerospace engineer from the Gemini space program, and a former exec of Honeywell (Larry Goshorn). By 1972 they went public, and by 1974 were the 4th largest minicomputer make in the world, and by 1986 they exited that business. Boom and bust was very much the the 1970’s for many companies though, and while it was boom times, General Automation was pioneering in many ways.

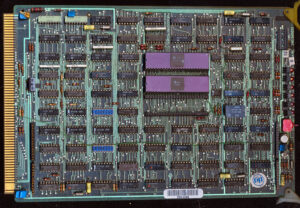

In 1973 another well known semiconductor company was started, Synertek, with funding from Bulova Watch Company, Victor Comptometer, AT&T, and..General Automation, who needed a reliable source for memory chips for its computers at the time. Synertek would go on to source the custom CPU GA designed for their GA-16 minicomputer. The GA16 was a LSI (2 chip) version of their SPC-16 line of computers that originally debuted in 1971. It was compatible with the original SPC-16 line which helped it become quite popular. GA marked the GA-16 in 2 main flavors originally, the GA16/110 basic computer, and the full of GA-16/220 which had an additional ‘CPU’ board that added DMA support and additional I/O capabilities. What made this ‘mini computer’ interesting was that it was also available as a bare board, an early Single Board Computer, with just the GA-16 processor. This allowed it to be integrated into all sorts of industrial applications.

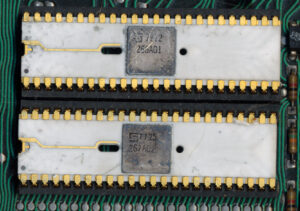

The GA-16 CPU was a 16-bit processor made on Synertek’s NMOS process. It was composed of two 48-pin ceramic DIPs. The 266A01 (later the 941A02) was the RALU – Register and Arithmetic Logic Unit. This handled all the functional bits of the processor, executing the instructions. The second chip was the 267A02 (later the 940A02) CROM, the Control and Real Only Memory. This handled all the control (instruction decode and gating) of the RALU, as well as stored the microcode, the instruction set, of the CPU. All Registers were on the RALU except the instruction register which was on the CROM (as it was needed for instruction decoding). Additional instructions could be added (as was the case of the GA-16/440) by adding an additional CROM chip. This is similar to the DEC LSI-11 series of processors, where the instruction set could be added to with additional chips.

The GA-16 had 91 basic instructions and 16 general purpose registers (8 primary and 8 secondary, for task switching), a Program Counter Register (P), and a Working Register – W (Accumulator). The instruction set supported hardware MULT and DIV, a rarity of that time. The processor could directly address up to 64K of memory. These ran at a 500ns cycle time (2MHz) though this was primarily limited not by the CPU, but by memory. Later versions (the GA-16/4×0) increased this to 4.2MHz (240ns cycle time).

The GA-16 found wide use in industrial automation, as well as mini-computer use. THe university of Stockholm, in Sweden, used a GA-16/440 to build a digital mapping system. THe GA-16 excelled at math, having an very capable hardware ALU. It landed itself well to applications where math was involved, and raw speed was less important. Many CNC milling, drill press and other equipment ran on GA-16 computers. a GA-16/220 is also used at the Darlington Nuclear Power Plant in Ontario Canada. Its job is to handle automatic shutdown of the reactor if ever needed. It is paired with a DEC LSI 11/23 microcomputer as a backup. Using two completely different computer types increases reliability, the diversity strategy, as a problem with one system is unlikely to be the same in the other.

IER GA-16 chipset 1991-1992 vintage (from an eBay auction as I haven’t found one cheap enough to add to the museum yet)

By 1980 the mini-computer market was nearly gone and GA was having a hard time making any money. They sold their minicomputer operations to a company called ‘Industrial Electronic Resources LLC, in Corona, CA which specialized in supplying, and repairing industrial computers. GA went on to make microcomputers, and fault tolerant hardware and software, before eventually going bankrupt in the early 2000’s.

IER, however, lived on, continuing to make and service GA-16 processors across the world. These computers continued to be widely used in industry. One of the largest users of GA-16 computers is Excellon, which used them in many of their CNC equipment for decades, so in 2014 they bought their supplier, IER. Excellon continues to make and service GA-16 components for their legacy equipment, once a customer of General Automation, now they own it.