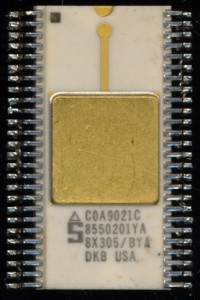

CPU of the Day: Military Signetics 8X305 Processor

Some time ago we talked about the history of the Signetics 8X300 line of processors. Originally released as the SMS300 in 1975 by SMS, the design was bought by Signetics. It was a fairly unique 8-bit bipolar design, running at 8MHz. Its focus was signals processing, long before dedicated DSP’s such as the TI TMS320 came about. The design was updated in 1982 to add some additional instructions and data handling.

Since it excelled so well at signals processing, the design worked well for military applications, where signals processing was of great use (interpreting data from a host of, usually, RF sensors. The 8X305 was made in the normal 50 pin DIP, a 68 pin LCC, and an unusual 52 pin flat pack for military use. In the 52-pin package the extra 2 pins are simply ‘No Connects’. (In the 68 pin version the extra 18 pins are divided amongst extra VCC, VR, GND, and N/C).

For military applications the greatest importance is on reliability. This takes the form of three main areas:

Mechanical: How well can the design handle shocks, and vibrations, usually this is handled through better bonding wires, and more rigid package specs/inspection.

Electrical: How well can the device tolerate not great electrical conditions, higher reliability is achieved when the device can operate with a voltage that may very up to 10%, rather then the 5% or less commercial devices are designed to.

Temperature: This is closely related to mechanical, as temperature stability requires the package to be damaged by expansion/contraction in wild temperature swings. Obviously the silicon die itself needs to work with the same electrical characteristics at different ends of the temp range. Many electrical parameters (such as resistance, and biasing) change over temperature, so the device must handle this. Typical military spec is -55C-125C (-67F-257F). A range of 180C, from well below freezing, to well above boiling.

This Signetics 8X305 (Drawing # 8550201YA) is rated at -55-125C at 5V +/- 10% running at 8MHz. It meets all the mechanical/inspection and testing requirements of MIL-STD-883 Class B. This type of design work is well understood, and now a days, rather routine. Making electronics work at 125C is no longer an engineering feat. But then, what if we need more? Lots more.

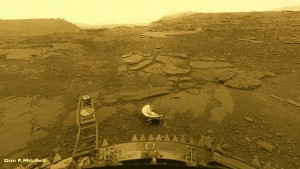

Recently NASA contracted with Ozark Integrated Circuits to do just that. NASA wants a process kit for IC’s that will run happily at 500C (932F) . At this temperature lead and tin have melted, and aluminum isn’t even very solid. If that sounds a bit inhospitable, you’d be right, and its exactly the conditions NASA faces with designing a rover for use on our nearest neighbor, Venus.

Ozark previously created such a process good for up to 350C, but thats still not hot enough for Venus. Ozark is using a silicon carbide substrate, and some other proprietary methods. They will not actually produce the chips for NASA, but rather licenses the methods to do so to a foundry service of NASA’s choosing, who will then manufacture and test them.

In the upper atmosphere, temps are below 0, and at the surface, atmospheric pressure is 90 times greater than on earth, another challenge for making a chip, with a die recessed in a sealed cavity. Such requirements, and the technology to meet it, will greatly enhance our exploration abilities, and no doubt, trickle down in some way, to the electronics we use each day.

Posted in:

CPU of the Day