Russian Computers on the Buran Shuttle

In the 1970’s and the 1980’s the Soviets developed and successfully flew their own version of the Space Shuttle. It was called the Buran. In many ways it was an enhancements of the US Space Shuttle, based on what the Soviets saw as deficiencies in the US design. One of the biggest differences was the piloting. The US STS (Shuttle Transport System) was designed to be a crewed vehicle. The computers assisted the pilot/co-pilot in launch, orbit, and recovery. Many of the functions on the STS can be handled by the computers (the Flight Computers were based on the IBM System/4 Pi) but the pilot was needed to handle the rest. The Soviets, on the other hand, designed the Buran to be able to launch, orbit, and land fully automatically. This meant the computers has to be very robust, and the programming even more so. The computers had to respond quickly to chaning inputs, and be able to handle failures gracefully. While each mission would have a set profile, unknown conditions would cause deviations that the computers must detect, analyse, and properly handle. Preferably without wrecking the multi-billion ruble space craft.

In the 1970’s and the 1980’s the Soviets developed and successfully flew their own version of the Space Shuttle. It was called the Buran. In many ways it was an enhancements of the US Space Shuttle, based on what the Soviets saw as deficiencies in the US design. One of the biggest differences was the piloting. The US STS (Shuttle Transport System) was designed to be a crewed vehicle. The computers assisted the pilot/co-pilot in launch, orbit, and recovery. Many of the functions on the STS can be handled by the computers (the Flight Computers were based on the IBM System/4 Pi) but the pilot was needed to handle the rest. The Soviets, on the other hand, designed the Buran to be able to launch, orbit, and land fully automatically. This meant the computers has to be very robust, and the programming even more so. The computers had to respond quickly to chaning inputs, and be able to handle failures gracefully. While each mission would have a set profile, unknown conditions would cause deviations that the computers must detect, analyse, and properly handle. Preferably without wrecking the multi-billion ruble space craft.

The main computer of the Buran is actually 4 independent systems that receive the same inputs. The clock in generated externally (with 4 backups) so that each computer is in perfect time (the STS uses software to ensure the computers are in time, rather then hardware). Redundancy is achieved by the voting system. Each computers outputs are compared, if one computers output is different, it is automatically shut down, leaving the 3 remaining computers. These computers are powered by a clone of the DEC PDP-11. The Soviet’s ‘acquired’ a few PDP/11 systems and then copied and cloned them into many different systems. The most common is the 1801 a 5MHz NMOS PDP-11 type device. The Buran used the 1806, which is the CMOS version. Here is a general overview of the flight computer.

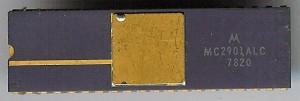

In addition to the 1806 there were many sub-systems with their own processors. Details on these are a bit thin, however looking at other Soviet space computer designs it is very likely that many of these used the 134IP3 series of ALUs (a clone of the 54L181 TTL 4-bit ALU). This chip is also used in the Argon-16 and Argon 16A computers of the Soyuz and Progress spacecraft that are still in use today. Bit-slice devices were used extensively for many Soviet designs as it gave them a great ability to design custom processors to meet the applications needs. The Argon-17, which was used for anti-ballistic missile work, was based on the 583 series, an 8-bi slice processor. The C100 and C101 computers (used as weapons computers on the MiG-29) also use a BSP design.